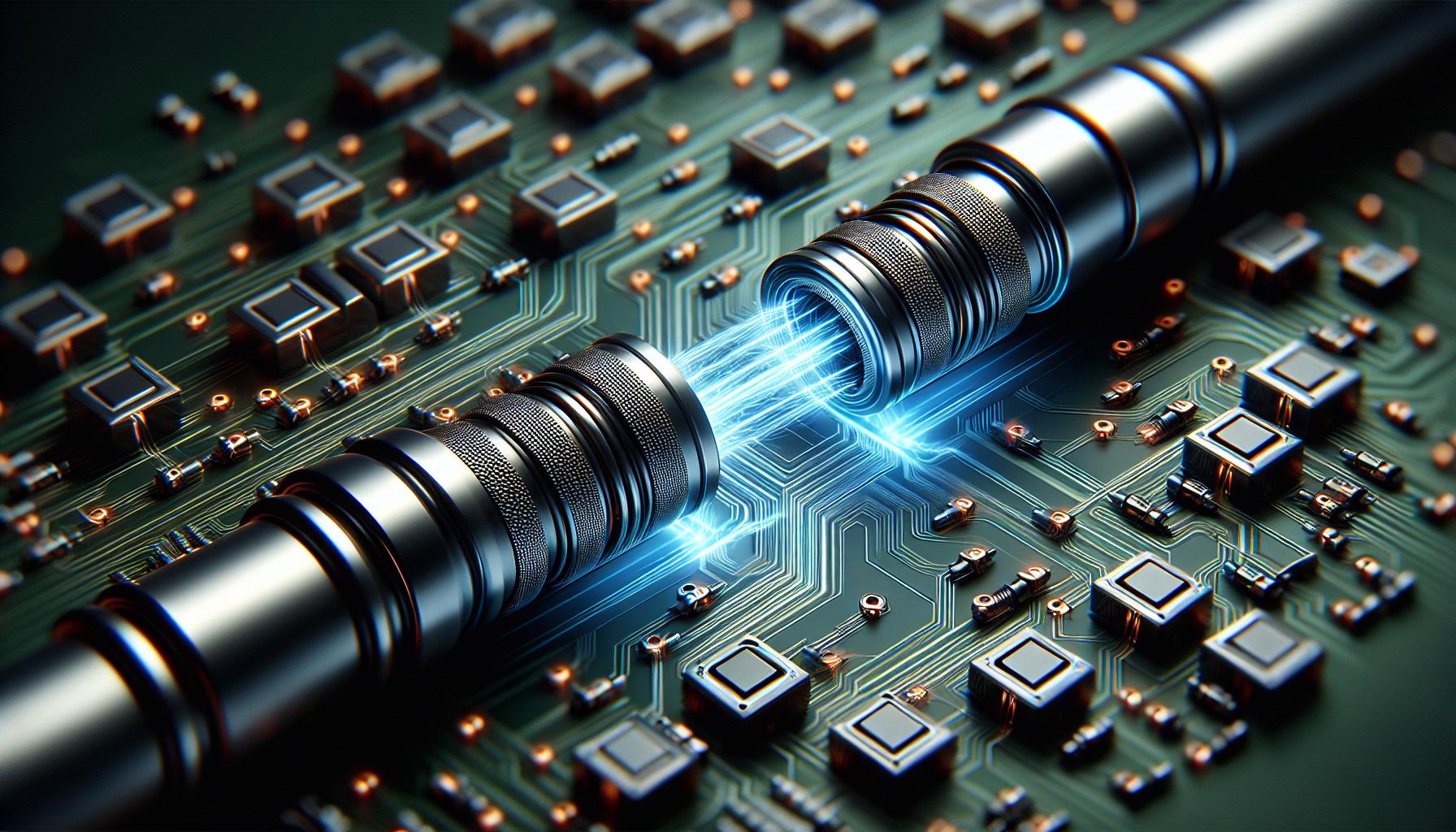

In a world where technology drives daily life, ensuring device safety is crucial. Magnetic connectors have emerged as a reliable solution to prevent short circuits, protecting both devices and users. This article explores the science behind magnetic connectors, their design benefits, and how they effectively minimize the risk of electrical failures.

Overview of Magnetic Connectors

Magnetic connectors play a crucial role in enhancing device safety by preventing short circuits. Their unique design aids in establishing secure connections while minimizing the risk of electrical failures.

Definition and Purpose

Magnetic connectors consist of components that use magnetic attraction to maintain circuit integrity. They connect devices using magnets rather than traditional plugs or sockets. The primary purpose is to create a safe, reliable connection that disengages easily under stress, protecting devices from damage. A reputable Magnetic Connector Manufacturer ensures high-quality designs that maximize safety and efficiency.

Types of Magnetic Connectors

- Magnetic Charging Connectors: Typically used in devices like smartphones and laptops, these connectors support rapid charging while ensuring an easy, secure attachment.

- Data Transfer Connectors: Utilized in technology such as external drives, these connectors allow for data transmission while offering quick disconnection to prevent potential data loss.

- Custom Magnetic Connectors: Designed for specific applications, these connectors cater to unique device requirements, ensuring a tailored and effective connection solution.

Mechanism of Action

Magnetic connectors utilize magnetic fields to establish and maintain secure electrical connections. This technology minimizes the risk of short circuits by allowing connections to disengage safely under stress, preventing damage to devices.

How Magnetic Connectors Work

Magnetic connectors function through magnetic attraction between complementary ends. When aligned correctly, the magnets pull the connectors together, forming a stable electrical link. If a significant force is applied, the connector disconnects automatically, breaking the circuit and reducing the risk of short-circuit conditions. This mechanism protects both the connector and the connected device from potential electrical damage.

Role in Circuit Design

Magnetic connectors play a vital role in circuit design by enhancing safety and reliability. Engineers strategically incorporate magnetic connectors into designs to ensure that connections remain intact during normal operation but can release safely under unintended stresses. This design approach mitigates the risk of component failure and protects sensitive electronic parts from excessive current discharge or physical stress. By integrating magnetic connectors, circuit designs achieve greater longevity and performance while reducing the likelihood of electrical hazards.

Advantages of Using Magnetic Connectors

Magnetic connectors offer significant benefits in device safety and efficiency, particularly in preventing short circuits and enhancing durability.

Prevention of Short Circuits

Magnetic connectors effectively minimize the risk of short circuits. Their design allows connections to break cleanly under stress, avoiding damage to both devices and connectors. When force exceeds a specific threshold, magnetic connectors disengage, ensuring that electrical pathways remain intact during normal use. This disengagement prevents mishaps, such as tangling of cables or accidental disconnections, that could lead to electrical failures. By maintaining reliable connections while also allowing safe release, these connectors significantly improve overall device safety.

Enhanced Durability

Magnetic connectors feature robust construction that contributes to their durability. Unlike traditional connectors that may suffer from wear and tear due to frequent plug-and-unplug actions, magnetic connectors endure less physical stress. Their ability to disengage without forcefully pulling on connecting cables reduces the likelihood of damage. Additionally, these connectors resist corrosion and overheating, further extending their lifespan. Their durable design minimizes the need for replacements and repairs, making them a cost-effective choice in device manufacturing and user experience.

Applications of Magnetic Connectors

Magnetic connectors find extensive use across different sectors due to their flexibility and reliability in preventing short circuits.

Consumer Electronics

Magnetic connectors play a vital role in consumer electronics, particularly in smartphones, tablets, and laptops. Their design enables fast charging through magnetic charging connectors, facilitating rapid power transfer without the risk of failure during disconnection. Magnetic data transfer connectors also reduce the chance of data corruption by allowing quick disconnects when devices are pulled or moved unexpectedly. This technology enhances user experience and device longevity, minimizing maintenance costs tied to wear and tear.

Industrial Uses

In industrial applications, magnetic connectors provide efficient solutions for heavy machinery and equipment. They simplify modular connections and disconnections, allowing quick maintenance or replacement without shutting down operations. Additionally, magnetic connectors improve workplace safety by preventing short circuits and equipment damage caused by accidental disconnections. Their robust construction withstands harsh environments and high-frequency use, making them indispensable in manufacturing, robotics, and telecommunications.

Conclusion

Magnetic connectors stand out as a crucial innovation in enhancing device safety and preventing short circuits. Their unique design allows for secure connections that can disengage safely under stress, significantly reducing the risk of electrical failures. This reliability not only protects devices but also extends their lifespan, making them an ideal choice for various applications.

As technology continues to evolve, the role of magnetic connectors becomes increasingly vital in ensuring efficient and safe operation across consumer electronics and industrial machinery. By incorporating these connectors, manufacturers can improve user experience while minimizing potential hazards, paving the way for safer and more durable devices in the future.

Frequently Asked Questions

What are magnetic connectors?

Magnetic connectors are electrical connectors that utilize magnetic attraction to secure connections and simplify disconnection. This design minimizes risks of short circuits while maintaining circuit integrity.

How do magnetic connectors enhance device safety?

Magnetic connectors improve device safety by allowing connections to detach automatically under stress. This feature prevents damage to both the connector and the device, significantly reducing the risk of electrical failures.

What applications do magnetic connectors have?

Magnetic connectors are widely used in consumer electronics like smartphones and laptops for rapid charging and data transfer. They also serve industrial equipment, enabling quick maintenance and enhancing safety in operational environments.

What types of magnetic connectors are available?

Common types of magnetic connectors include magnetic charging connectors for devices, data transfer connectors for external drives, and custom connectors tailored for specific applications, each designed to meet unique requirements.

How do magnetic connectors work?

These connectors function through magnetic fields that establish secure electrical connections. The magnetic attraction between complementary ends allows for stable links that can safely disconnect under significant force to prevent damage.

What are the benefits of using magnetic connectors?

Magnetic connectors offer several advantages, including enhanced durability, reduced wear and tear, lower risks of short circuits, and cost-effectiveness due to less frequent need for replacements and repairs.